Batch Neutralizing Plant

Batch Neutralizing Plant Specification

- Model No

- BNP-5000

- Efficiency (%)

- Over 98%

- Automation Grade

- Fully Automatic

- Production Capacity

- Up to 15000 Litres per Day

- Accessories

- pH Meter, Dosing Pumps, Agitator, Safety Valves, Feed & Discharge Pumps

- Driven Type

- Electric

- Installation Guideline

- Foundation Required, Must be Installed on a Level Surface, Follow Electrical Safety Norms

- Frequency

- 50/60 Hz

- Temperature Range

- Ambient to 120C

- Motor Power

- 7.5-15 HP

- Usage & Applications

- Neutralization of Acidic/Alkali Solutions in Chemical, Pharmaceutical, and Food Processing Industries

- Speed

- Variable (Adjustable By VFD)

- Type

- Batch Neutralizing Plant

- Material

- Stainless Steel (SS 304/316)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control Panel

- Drive Type

- Electric Motor Driven

- Voltage

- 380-440 V

- Power

- 10-25 kW (As per model)

- Weight (kg)

- 1200-3500 kg (Model dependent)

- Dimension (L*W*H)

- 3200 x 2100 x 2500 mm (Approx)

- Color

- Silver / Customized

- Capacity

- 500-5000 Litre per batch

- Features

- Corrosion Resistant, Easy to Operate, Eco-Friendly Operation, High Durability, Low Maintenance

- Surface Finish

- Mirror/Matte Polished

- Machine Type

- Batch Processing System

- Power Consumption

- Depends on model and batch size

- Cleaning System

- CIP (Clean-In-Place) Optional

- Heat Exchanger

- Optional (for temperature control)

- Safety System

- Emergency Stop, Interlock Alarms, Overload Protection

- Inlet/Outlet Size

- 2"-4" Inch (as per requirement)

- pH Range Handled

- 1 to 14

- Sealing Method

- Mechanical Seal

- Design Pressure

- Up to 4 Bar

- Mixing Time

- 15-45 minutes (batch depending)

- Noise Level

- Under 65 dB

- Agitator Type

- Top Mounted, High Shear

- GMP Compliance

- Available for Pharma Use

- Level Indicator

- Digital/Analog Level Sensors

- Discharge Mode

- Bottom Valve

- Tank Lining

- PTFE/FRP/Yarn Liner Available on Request

Batch Neutralizing Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 3 Units Per Year

- Delivery Time

- 6-8 Days

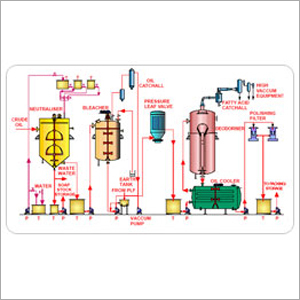

About Batch Neutralizing Plant

Recognized as a quality conscious organization, we are engaged in providing the best quality Batch Neutralizing Plant. The offered plant is widely demanded in the market for maintaining pH level of various corrosive liquid wastes discharged from industrial processes. Utilized as important utility to decrease level of hazardous chemicals, this plant is manufactured using excellent quality components as per international quality standards. Also, this Batch Neutralizing Plant is admired for its smooth neutralization.

Key Points:

- Optimum throughput

- Excellent functioning

- Easy to maintenance

- Longer life

Efficient Neutralization Process

The BNP-5000 offers rapid and uniform neutralization of acidic and alkaline solutions, achieving high reaction efficiency with a variable-speed agitator controlled via VFD. The batch system enables complete process flexibility for chemical, pharmaceutical, and food industry requirements while reducing energy consumption and minimizing operational noise below 65 dB for a safe workplace.

Advanced Safety and Automation

This neutralizing plant features comprehensive safety systems, including digital/analog level indicators, emergency stop switches, interlock alarms, and overload protection. Its PLC-based control panel ensures automated operation, real-time process monitoring, and precise adjustments, enhancing both safety and productivity for users. Optional Clean-In-Place (CIP) supports stringent hygiene and easy maintenance.

Customizable Design and Applications

Available with PTFE/FRP/Yarn liners, assorted inlet/outlet sizes, optional heat exchanger, and tailored finishes, the plant meets strict GMP requirements and diverse processing needs. Its modular construction supports installation on leveled foundations and adherence to electrical safety norms, guaranteeing compatibility for many application environments. Accessories such as dosing pumps and pH meters add further versatility.

FAQs of Batch Neutralizing Plant:

Q: How does the Batch Neutralizing Plant ensure consistent mixing and neutralization within each batch?

A: The plant utilizes a top-mounted high shear agitator with variable speed adjustment via VFD, guaranteeing thorough mixing and uniform neutralization of acidic or alkaline solutions in each batch by optimizing the blending time (1545 minutes) as per process requirements.Q: What safety features are included in the BNP-5000 to protect operators and maintain process integrity?

A: Safety is ensured through emergency stop switches, interlock alarms, overload protection, and digital or analog level sensors. These mechanisms help prevent operational hazards and safeguard the plant during processing, contributing to GMP compliance for pharmaceutical uses.Q: When should the optional heat exchanger and CIP cleaning system be incorporated into a Batch Neutralizing Plant?

A: The heat exchanger is recommended when temperature-sensitive neutralization is required, supporting a range from ambient to 120C. The CIP cleaning system should be included for frequent batch changes, stringent industry hygiene standards, or to streamline maintenance in regulated environments.Q: Where is the ideal installation location for the Batch Neutralizing Plant BNP-5000?

A: The plant should be installed on a level, stable surface with proper foundation, complying with electrical safety norms. It fits seamlessly in chemical, pharmaceutical, and food processing environments, with sizing options adapted as per site requirements and operational workflow.Q: What is the process for monitoring and controlling pH levels during neutralization?

A: The plant provides pH meters and dosing pumps for real-time pH monitoring and chemical dosing, supported by a PLC-based control panel. This setup allows for precise adjustment and continuous feedback, ensuring accurate pH regulation from 1 to 14 throughout the operation.Q: What benefits does the BNP-5000 offer for industries seeking eco-friendly and cost-effective neutralization?

A: Delivering over 98% operational efficiency, the BNP-5000 boasts low power consumption, minimal maintenance, corrosion-resistant construction, and eco-friendly operation. Its automated capabilities help reduce manual labor, enhance workplace safety, and lower overall operational costs for sustainable processing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free