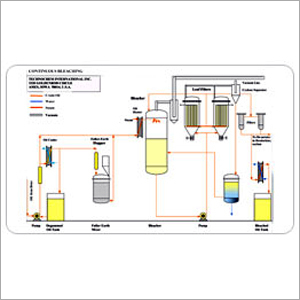

Continuous Bleaching Plant

Continuous Bleaching Plant Specification

- Power

- 45 to 200 kW (as per capacity)

- Condition

- New

- Product Type

- Continuous Bleaching Plant

- General Use

- Edible Oil Processing, Bleaching of Oils

- Material

- Mild Steel, Stainless Steel

- Capacity

- 10 - 300 TPD (Tons Per Day)

- Weight (kg)

- Custom / As per requirement

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Mixer Type

- Agitator

- Shaft

- Alloy Steel Shafts

- Drive Type

- Electric Motor Drive

- Voltage

- 380-440 V

- Motor

- Electric

- Dimension (L*W*H)

- As per plant design

- Feature

- High Efficiency, Energy Saving, Low Maintenance

- Color

- Metallic / As per client specification

- Application

- Oil Refinery, Industrial Bleaching

- After Sales Support

- Available

- Automation Grade

- Fully automatic

- Control Panel

- Touch Screen HMI with Advanced Controls

- Phase

- Three Phase

- Operating Temperature

- 110°C to 140°C

- Mounting Type

- Skid Mounted/Customized Layout

- Spare Parts Availability

- Yes, On-demand

- Safety Features

- Emergency Stop Button, Overheat Protection

- Residue Discharge

- Automatic Continuous Discharge

- Heating System

- Thermic Fluid Heater / Steam

- Corrosion Resistance

- Yes

- Service Life

- Long Service Life

- Design Standard

- Complies with International Standards (ISO/CE)

- Installation Service

- Provided

- Noise Level

- Low

- Feed Material

- Crude Vegetable Oil

- Pre-Treatment

- Degumming & Neutralization Possible

- Working Pressure

- Atmospheric or Customized

Continuous Bleaching Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 3 Units Per Year

- Delivery Time

- 6-8 Days

About Continuous Bleaching Plant

We are one of the notable manufacturers, exporters and suppliers of superior quality Continuous Bleaching Plant. The offered plant is ideally used in chemical industry for bleaching purposes. Known for its high durability and easy operations, the provided plant is manufactured using premium grade components and innovative techniques. Moreover, the offered Continuous Bleaching Plant can be bought by our precious patrons at rock bottom rates.

Key Points:

- Sturdy design

- Reliable to use

- Impeccable performance

- Easy maintenance

Advanced Control and Automation

Equipped with a computerized PLC control panel and an intuitive Touch Screen HMI interface, the plant enables fully automatic and precise operation. The automation grade ensures consistent results and minimizes manual intervention, supporting high efficiency and low maintenance in industrial and edible oil bleaching processes.

Efficient and Safe Bleaching Process

The plants heating system, using thermic fluid or steam, sustains optimal operating temperatures tailored for oil bleaching. Safety mechanisms like emergency stop buttons and overheat protection enhance workplace security, while corrosion-resistant materials and continuous residue discharge guarantee reliable, long-term performance.

Customizable Design and Expert Support

Built to international standards with skid-mounted or customized layouts, the plant meets diverse site requirements. After-sales support, installation service, and on-demand spare parts availability ensure seamless operation and minimal downtime, making it an ideal choice for manufacturers, exporters, and service providers in the oil industry.

FAQs of Continuous Bleaching Plant:

Q: How does the Continuous Bleaching Plant enhance the efficiency of oil refining operations?

A: The plants fully automatic, PLC-controlled system ensures continuous processing, stable operating temperatures, and automatic residue discharge, resulting in consistent product quality, energy savings, and reduced downtime during edible oil bleaching.Q: What types of heating systems are available for this bleaching plant?

A: You can choose between a thermic fluid heater or steam-based heating system, both designed for precise temperature control (110C to 140C) to meet specific requirements in oil refinery operations.Q: When is pre-treatment like degumming and neutralization necessary before the bleaching process?

A: Pre-treatment is advisable for crude vegetable oils to remove impurities and prepare the feed materialthis step ensures optimal bleaching efficacy and refined oil quality during further processing.Q: Where can the Continuous Bleaching Plant be installed, and what layout options are offered?

A: It can be installed at oil refineries or industrial facilities. The plant is available in skid-mounted or customized layout formats to accommodate varied space and workflow needs, with professional installation services provided.Q: What is the process for operating the plant and monitoring its performance?

A: Operators use the Touch Screen HMI and advanced controls to set process parameters, monitor temperature, pressure, and residue discharge, while the automated system manages all phases, ensuring safe and efficient bleaching throughout.Q: What are the main benefits of using this continuous bleaching plant in industrial applications?

A: Key benefits include high process efficiency, reliable safety features, low operational noise, energy savings, robust corrosion resistance, and extended service life, along with the assurance of dealer, exporter, and service provider support in India.Q: Is after-sales support and spare parts availability guaranteed for ongoing maintenance?

A: Yes, ongoing maintenance is supported by comprehensive after-sales service and on-demand spare parts availability, ensuring uninterrupted plant operation and swift resolution of any technical concerns.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free