Winterization Plant

Winterization Plant Specification

- Frequency

- 50-60 Hz

- Production Capacity

- 10 to 100 tons/day

- Driven Type

- Electric

- Automation Grade

- Automatic

- Speed

- Variable

- Installation Guideline

- Onsite Technical Support Provided

- Temperature Range

- -10C to +20C

- Accessories

- Filters, Heat Exchangers, Chilling System, Pumps

- Motor Power

- 5 HP - 20 HP

- Model No

- WP-2024

- Efficiency (%)

- 98%

- Usage & Applications

- Edible Oil Processing, Dewaxing, Removal of Waxes and Lipids

- Type

- Winterization Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based

- Drive Type

- Electric

- Voltage

- 220-440 V

- Power

- 15-50 kW

- Weight (kg)

- 3500-8000 kg

- Dimension (L*W*H)

- Customized

- Color

- Steel Grey

- Capacity

- 10 TPD to 100 TPD

- Features

- High Efficiency, Low Power Consumption, Sturdy Construction, Corrosion Resistant

- Machine Type

- Industrial Processing

- Power Consumption

- as per capacity

- Surface Finish

- Polished

- Turnkey Project Capability

- Yes

- Phase

- Three Phase

- Operating Pressure

- Atmospheric to Slight Vacuum

- Cooling System

- Brine/Chilled Water

- Safety System

- Overload Protection, Emergency Stop

- Processing Method

- Batch or Continuous

- Service Support

- Available

- Cleaning System

- CIP (Clean-In-Place) System

- Environment Compliance

- Meets International Standards

- Design

- Modular

- Heating Source

- Electric or Steam

- Insulation Type

- PUF/Glass Wool

- Noise Level

- Less than 70 dB

Winterization Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 3 Units Per Year

- Delivery Time

- 6-8 Months

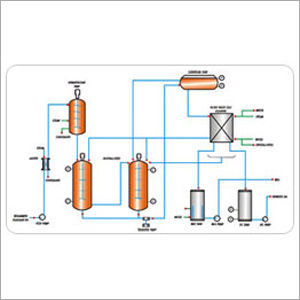

About Winterization Plant

Since our inception in the year 1994, we have been counted among prominent entities by offering top grade Winterization plant. Finding its applications on industrial level, the provided plant is used for oil refining purpose. Manufactured under the strict guidance of deft professionals, the offered plant is known for its functional fluency and easy operation. Moreover, we offer the provided Winterization Plant to our valued patrons at cost effective rates.

Key Points:

- Sturdy construction

- Extended durability

- Brilliant performance

- Low maintenance

Efficient Edible Oil Winterization

The WP-2024 Winterization Plant enhances oil quality by efficiently removing waxes and lipids through precise temperature control and filtration. Its automated batch or continuous process ensures consistent product purity and clarity. Advanced chilling and heating systems support optimal dewaxing conditions, while high-efficiency components minimize energy usage and maximize throughput.

Modular Design & Onsite Support

Built with a modular structure, the plant accommodates customized installations suited to production demands. Comprehensive onsite technical support is included, covering installation, commissioning, and maintenance. The turnkey project capability simplifies integration, ensuring a hassle-free expansion or upgrade for edible oil facilities.

FAQs of Winterization Plant:

Q: How does the Winterization Plant improve edible oil quality?

A: By operating within a controlled temperature range (-10C to +20C), the plant removes waxes and lipids from edible oils, resulting in clear, pure oil ideal for commercial applications. The advanced filtration and chilling systems enhance product consistency and appearance.Q: What processing methods are available with the WP-2024 model?

A: The WP-2024 offers both batch and continuous processing. This flexibility allows manufacturers to select the method that best suits their production capacity and workflow requirements, ranging from small to large-scale operations.Q: When is winterization necessary in the edible oil industry?

A: Winterization is required when producing oils that must remain clear and pourable at low temperatures, such as those used in food products and specialty applications. The process prevents formation of wax deposits and ensures oils retain desirable characteristics year-round.Q: Where can the Winterization Plant be installed, and is onsite technical support provided?

A: The plant can be installed in any industrial setting involved in edible oil processing. Installation guidelines are provided, and onsite technical support is available to assist with setup, commissioning, and troubleshooting.Q: What safety features are incorporated in the WP-2024 Winterization Plant?

A: It is equipped with overload protection, an emergency stop system, and noise levels kept below 70 dB to ensure operator safety and comply with workplace standards. The robust construction further minimizes operational risks.Q: How is cleaning performed in the plant, and what accessories are included?

A: The plant uses a CIP (Clean-In-Place) system for thorough internal cleaning without dismantling, ensuring hygiene and process continuity. Key accessories provided include filters, heat exchangers, chilling systems, and pumps for reliable operation.Q: What are the main benefits of using this modular, automatic system?

A: Users gain increased efficiency (up to 98%), lower power consumption, simple modular installation, corrosion-resistant durability, and full compliance with international environment and safety standards. The automatic PLC-based control system allows easy monitoring and adjustment for consistent high-quality output.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free